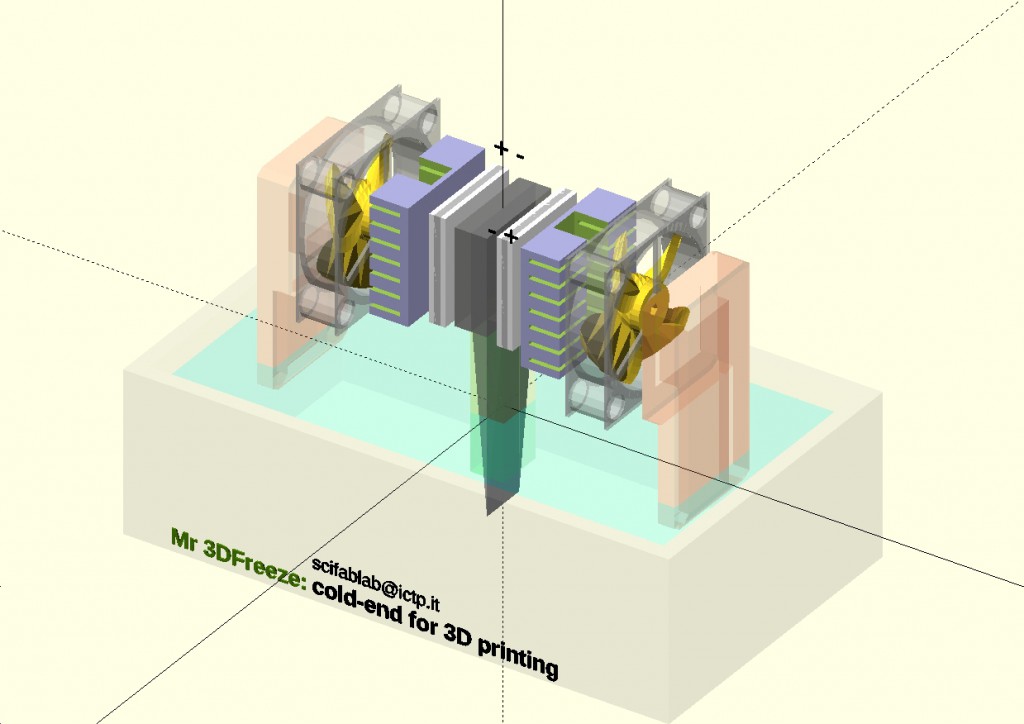

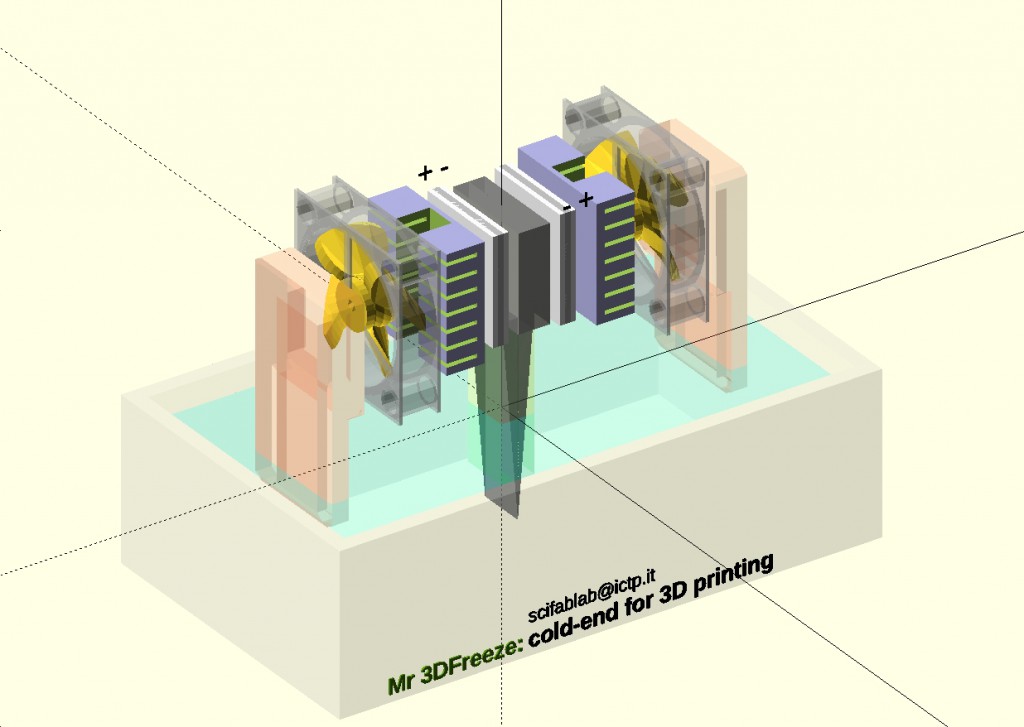

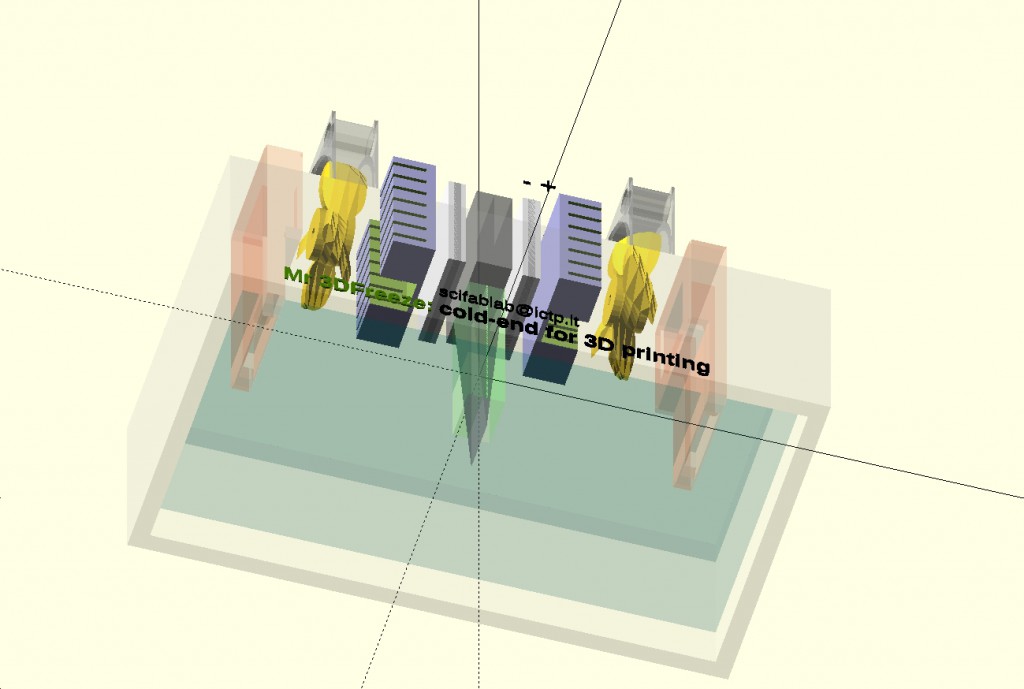

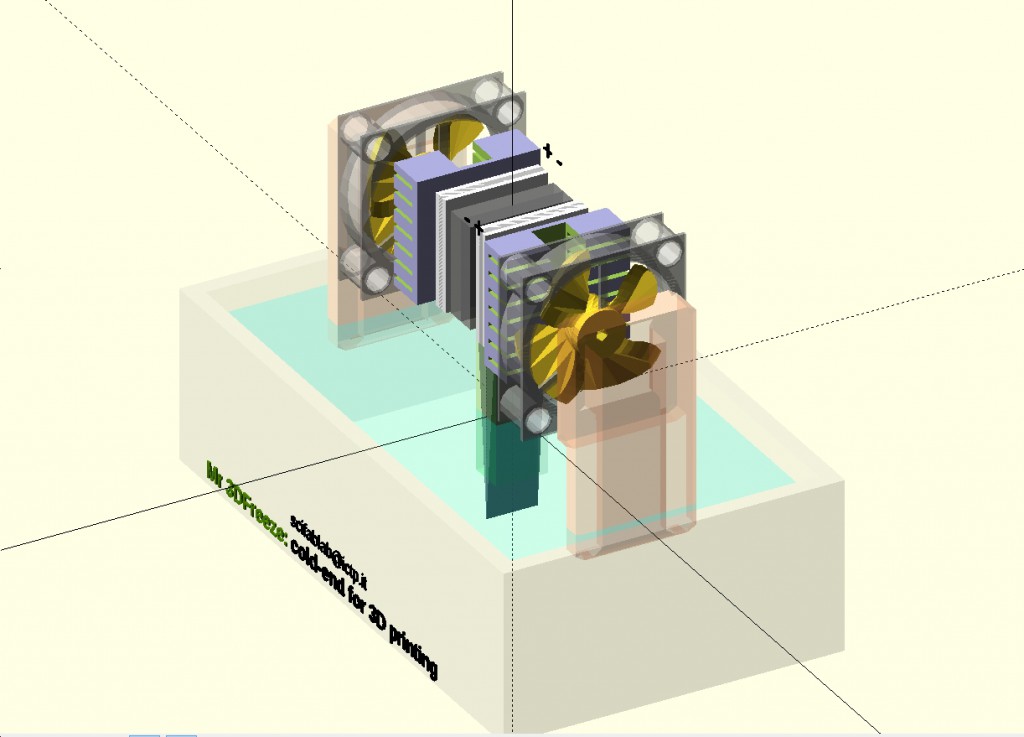

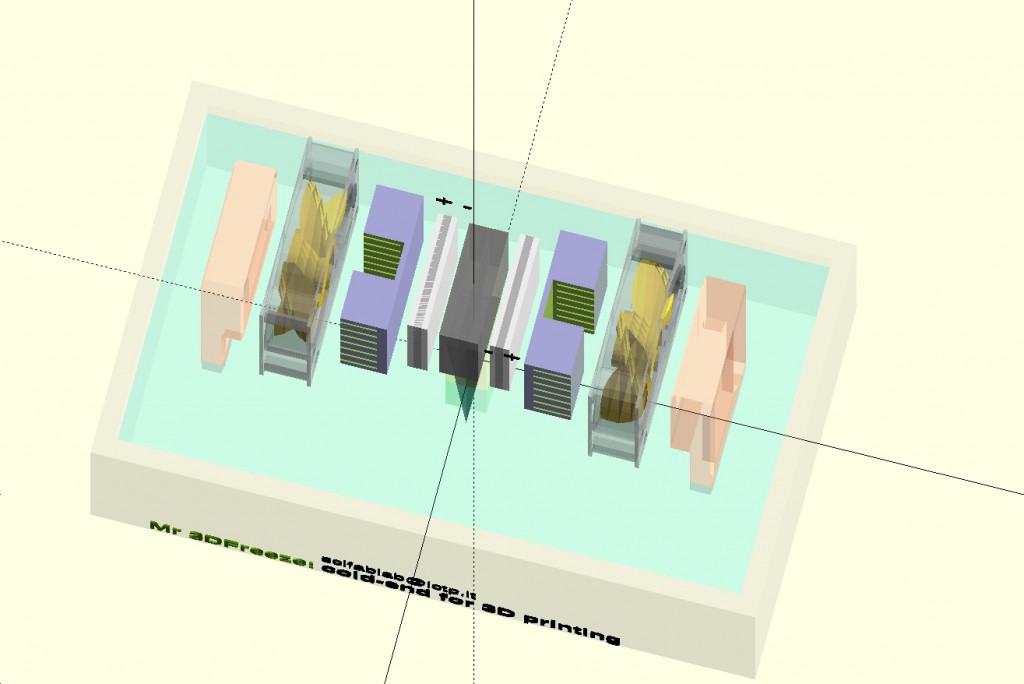

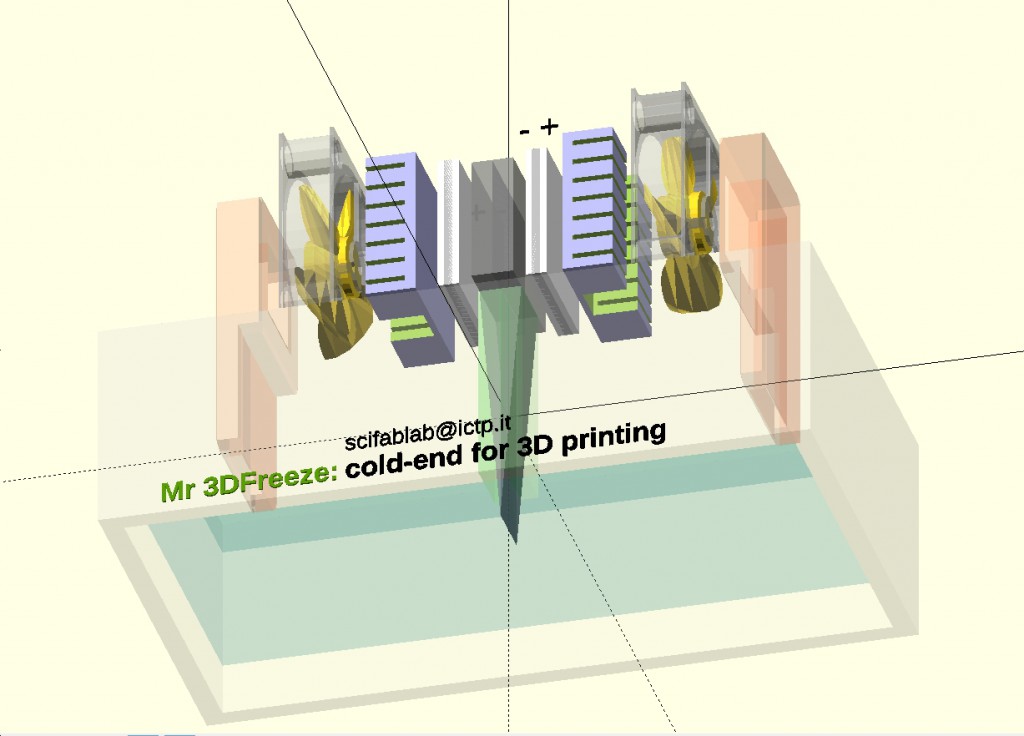

We introduce in the images below our first cold-end prototype for 3D printing by selective fast cooling (“freezing”) of a bath of melted material (having low melting-point like Wax and chocolate). This solution is based on thermoelectrical devices and is designed to work with standard RepRap (hot-end) 3D printers, with just simple adaptations of the extruder part, so that the same firmware and g-codes could be used. The printed Wax material can be easily recycled within the same freezing process avoiding any waste. Since Candle-Wax is easily available around the world, we believe the use of Mr 3DFreeze cold-end for the 3D printing of educational objects may find a fertile soil.

Category Archives: A Minimal Low-cost 3D Printer

Easy PET filament for possible 3D printing (first trial)

First tentative for an simple and fast method to produce filament from PET plastic bottles at room temperature (whithout pellets or fusion) by having in mind the possibility of using it for 3D printing at low cost (many improvements are still needed). Work is in progress

Primissimo tentativo per produrre filamento da una bottiglia di plastica PET pensando alla possibilità’ di riciclare facilmente per stampare altri oggetti in 3D usando “additive manufacturing technology”